Hongdefa European Standards Wheat Flour Mill Plant

- Capacity: process 80tonnes wheat per 24hours wheat flour mill machine with stainless steel

- Final Product: bakery flour, super fine flour, wheat meal, pasta, bread flour and so on.

- By-product: wheat bran for Animal feed.

| Hongdefa 80tonnes per 24hours wheat flour mill plant | |

|

hard wheat, soft wheat and durum wheat. |

|

It is a complete line of wheat cleaning, milling and packing.

—–Main Machines which is very most important in wheat flour mill plant .

A. Roller Mills

1)The partitioned paneling and swing-out feed module guarantee ideal access to the feeding and grinding rolls. This makes residue-free cleaning possible.

2) a pulse generator automatically adjust the feed material at the entrance door

3) bearing SKF

4)Sensor:Omron

B. Plan sifter

1) Material: High-strength alloy steel

2)up and down sifter circles with steel plate overall by bending

3)Transmission system using spring force component institutions

4)Sieve frames of wood coated with synthetic resin,without backwire

5)All the inside walls as well as the doors are provided with high-grade insulation

6)Vertical and horizontal clamping system.

C. PLC Control system.

It is working with CCTV surveillance system realize seamless integration by controlling all the wheat milling plant.

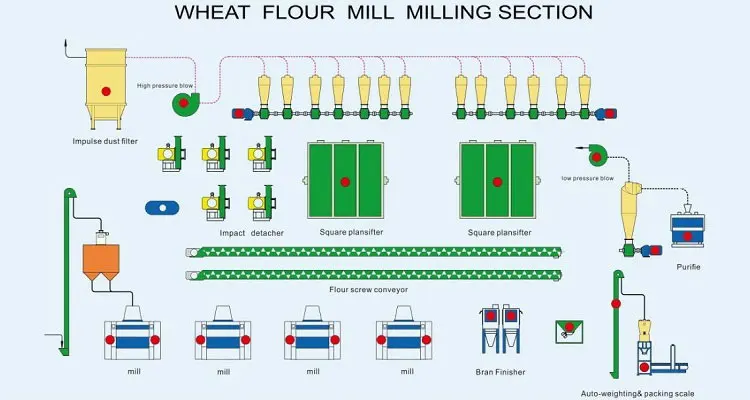

—Here is the flow chart for wheat flour milling section includes the automatic roller mill, plan sifter, dust collector, packing machines.

It is the main section in wheat flour mill machine processing line.

—In the wheat flour milling machine processing, it can get super fine flour, bakery flour, wheat meal, brown flour.

It can make what you want just like bread, biscuit, pasta, noodles, chappatti and so on.